We have standardization and professional service system

Ensure you enjoy the high quality and efficiency service.Ductile iron pipe in the medium and small caliber to give the connection between the pipe and the pipe, using socket or flange type interface method; ductile iron, allowable limit of the corner must have superior seismic resistance and sealing. The main components of ductile iron pipe are carbon, silicon, manganese, sulphur, phosphorus and magnesium.

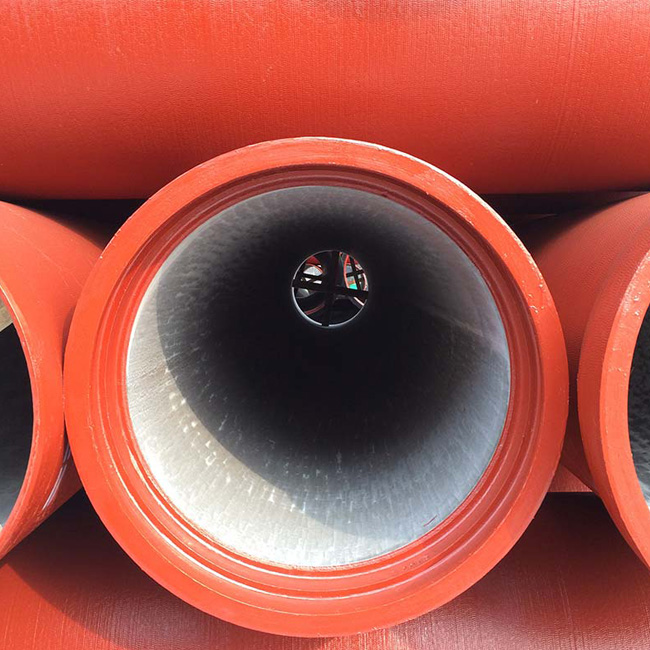

Ductile iron pipe is a type of cast iron pipe. The quality requires the spheroidization grade of cast iron pipe to be controlled as 1-3 grade (spheroidization rate》80%), thus the mechanical properties of the material itself ductile iron pipe finished library can be better improved, with the essence of iron and the performance of steel. After annealing, the metallographic organization of ductile iron pipe is ferrite plus a small amount of pearlite, with good mechanical properties, excellent anti-corrosion performance, good ductility, good sealing effect, easy installation, mainly used for municipal, industrial and mining enterprises water supply, gas transmission, oil transmission, etc.

In the ferrite and pearlite matrix distribution of a certain number of spherical graphite, according to the nominal caliber and the requirements of different elongation, the proportion of ferrite and pearlite in the matrix organization is different, small caliber pearlite proportion is generally not more than 20%, large caliber is generally controlled at about 25%.

In the low and medium pressure pipe network, ductile iron pipe has safe and reliable operation, low breakage rate, convenient and quick construction and maintenance, excellent anti-corrosion performance, etc.

In high pressure pipe networks, they are generally not used and have low pressure resistance. Due to the relative bulkiness of the pipe body, machinery must be used for installation. If water leaks after pressure testing, all pipes must be dug out, lifted to a height where the clamps can be placed, and installed to stop the leak.

1. Trench excavation

The width of the trench bottom should be calculated according to the following formula: B=D1+2(b1+b2)

Where: B - excavation width of the bottom of the pipe trench (mm) D1 - width of the outer edge of the pipe structure (mm) b1 - width of the working surface on one side of the pipe (mm) b2 - width of the support on one side of the pipe (mm).

2. Trench support

According to the trench soil quality, groundwater, trenching section, load conditions and other factors for design, require solid and reliable, prevent collapse, support shall not prevent the lower pipe and stable pipe.

3. T-junction pipes should have piers at the bend in vertical or horizontal direction. 4. When conveying drinking water, the pipeline should not pass through the toxic contaminated area, and protective measures should be taken if it must.

5. The external anti-corrosion coating of the ductile iron pipe should be selected according to the soil condition of the laying place with galvanized and epoxy asphalt coating or higher requirements.

6. After installation and pressure testing, it is advisable to flush the pipe with low chloride ion water and disinfect it with 0.03% potassium permanganate solution.

The information is provided by the ductile iron pipe supplier.

Copyright © Beijing Solaire International Corporation All Rights Reserved | Sitemap |