We have standardization and professional service system

Ensure you enjoy the high quality and efficiency service.Overview

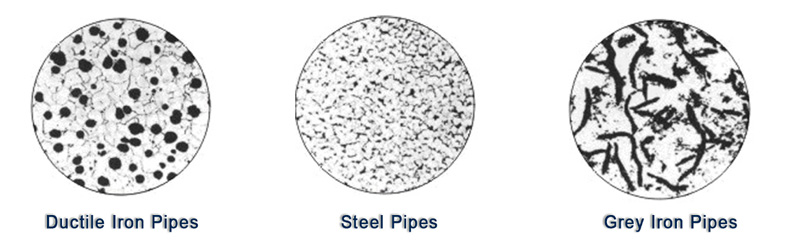

Ductile cast iron (also known as Spheroidal graphite iron or Nodular Cast Iron) was invented in 1940'. Ductile Iron retains the corrosion resistance of cast iron but has more than double the tensile strength. The essential differences between Ductile and Cast Iron lies in the shape of the graphite in the microstructure of the metal. In Cast Iron, the graphite is present in plate-like flakes, which makes Cast Iron brittle. But in Ductile iron, the shape of the graphite becomes a spheroidal nodule, which offers better mechanical properties and makes Ductile Iron sturdy, Structurally stronger and shock-proof.

Ductile Iron pipe is considered as the most preferred pipe material for water supply and pressure sewerage application all over the world. It offers higher Tensile Strength than Mild Steel and retains the inherent corrosion resistance of cast iron.

Application: ISO2531 and EN545 are used for drinking water.

Water supply for industrial /process plant application

Raw and clear water transmission (pumping and gravity main)

Distribution network of potable water

Application: EN598 is used for sewerage

Pumping irrigation station

Sewerage and waste water force main

Sewage treatment plants

● T-type (push-on and restrained type)

● K-Type joint

● Flanged joint

What are the uses of ductile iron pipes?

Ductile Iron Pipe is a type of pipe made of ductile iron that is commonly used for the transportation and distribution of potable water. Ductile iron pipe is a direct development from the earlier cast iron pipe that it has replaced.

What is the difference between an iron pipe and a ductile iron pipe?

Ductile iron has excellent corrosion resistance, tensile strength and yield strength. Unlike cast iron, ductile iron does not break when bent, making it more suitable for demanding applications. Ductile iron is a strong and reliable material for pipes, fittings and valves. Its disadvantage is that it is expensive.

What are the disadvantages of ductile iron pipes?

Corrosion rates are similar to cast iron and steel pipes.

Susceptible to external and internal corrosion.

Requires internal and external protection are systems.

Limited number of protection systems available.

Polyethylene packaging may be damaged.

What is the difference between mild steel and ductile iron pipe?

Ductile iron also has a higher fatigue strength than mild steel and can withstand repeated stresses without failure. Mild steel, on the other hand, may be better suited for applications that require flexibility rather than strength.

Copyright © Beijing Solaire International Corporation All Rights Reserved | Sitemap |