We have standardization and professional service system

Ensure you enjoy the high quality and efficiency service.Product Description

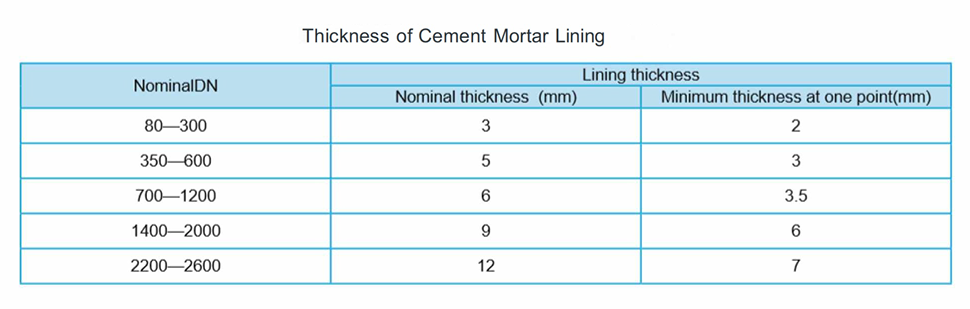

Cement mortar lining:

Cement mortar lining of ductile iron pipes is applied through centrifugal application method: When pipes are rotating on the lining machine, certain amount of cement mortar is poured into the pipes. Through high-speed revolution with acceleration about 30G under the centrifugal force, such cement mortar will fully cling to the internal surface of pipe, forming a dense and smooth lining with uniform thickness, which can provide good mechanical properties after curing for certain amount of time. Thickness of cement mortar lining shall comply with specifications as below:

Features of cement mortar lining:

1) Self-healing with the proceeding hydration reaction of cement:

the cement mortar lining will shrink gradually. Therefore, it is inevitable to form radial displacement and small cracks. This is a unique feature of cement mortar, which is allowable by the standard. Thus, no unfavorable influence on the mechanical stability of the lining will be brought by such cracks and radial displacement, as well as other cracks caused during manufacturing or transportation. When the pipe with cement mortar lining contact water, these cracks and radial displacement will be closed and healed along with expansion of the linings and continuous hydration of cement; therefore, the anticorrosion effect won’t be influenced.

2) Good mechanical property:

* Expansion coefficient:

The linear thermal expansion coefficient of cement mortar lining is 12 x 10-6/℃ , which is almost equal to that of ductile iron (11 x 10-6/℃ ). Therefore, it can reduce the risk of crack generation due to difference of thermal expansion coefficients.

Good adherence and anti-vacuum performance.

Good resistance to longitudinal bending and to ovality.

Good resistance to vibration and impact.

With excellent abrasion resistance, cement mortar lining can be used to convey raw water with highly abrasive particles.

* Excellent hydraulic performance:

We adopt centrifugal processing technology for its production of ductile iron pipes with cement mortar linings, which contributes to the lining’s smoothness. According to the test of Testing Center of China Institute of Water Resources and Hydropower Research, the equivalent roughness K of such lining is 0.030mm. Taking into consideration of the roughness caused by fittings, valves and other devices, as well as the tolerance, it is suggested that the value of K selected as 0.10mm for the design purpose.

Application fields:

the substances can be conveyed by various cement mortar linings. Ductile iron pipe with common silicate cement mortar lining is applicable for water-supply project; Ductile iron pipe with sulphur resistant cement mortar lining is applicable for water supply project and water transmission project with water quality. Ductile iron pipes with high-alumina cement mortar lining are applicable for the conduction of sewages and industrial wastewater containing certain chemical substances. Nitrile butadiene rubber (NBR) gasket.

Copyright © Beijing Solaire International Corporation All Rights Reserved | Sitemap |